Successful second quarter leads to a busy summer for Granada

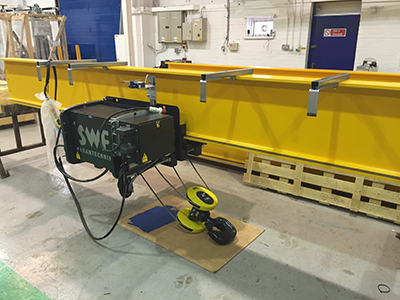

Following a significant run of customer orders in the second quarter of 2015, Granada have had a very busy summer. Maintaining tight installation windows, Granada have been working with partners SWF to ensure timely delivery of a range of cranes, including:

– 2 x 33m Span 5te Double Girder Crane

– 1 x 10te Double Girder Crane (pictured)

– 1 x 5te Monorail System (pictured)

– 1 x 20te Double Girder Crane

– 1 x 2te + 2te Single Girder Crane

– 2 x 5te Single Girder Cranes

– 1 x 5te + 5te Goliath Crane

In parallel, the Site Services teams have been installing these cranes, while looking after Granada’s customer needs on a day-to-day basis. In addition, Granada have had a good campaign of commissioning Davit Cranes on the Greater Gabbard Wind Farm, where Granada were chosen by GGOWL to manufacture, deliver and commission 140 replacement crane units. Granada continue to look after all the Davits on the Gwynt Y Mor Offshore Wind Farm, as part of the three year contract awarded earlier this year.

Looking forward to the final quarter of 2015, production of the 67 Davits for the Dudgeon Offshore Wind Farm is progressing well, with phased delivery anticipated to start soon. This is the second contract awarded to Granada for the Dudgeon Offshore Wind Farm. As Mark Sidwell, Director at Granada, commented,

“This confirms Granada as the UK’s leading offshore wind farm davit crane supplier, and is testament to the dedication and expertise of the Granada Renewable product and service division.”