-

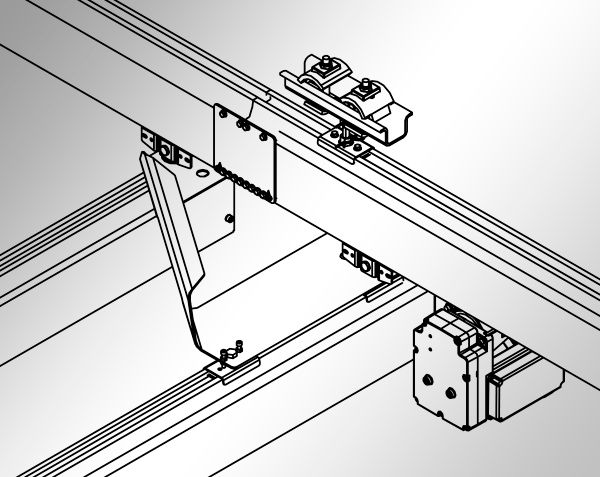

LIGHTster: Lightweight aluminium crane

LIGHTster: Lightweight aluminium craneDesigned for areas capable of

bearing only low static loads

Because of its low dead weight, the LIGHTster lightweight aluminium crane can use the loadbearing capacity of ceilings or structures to the full. Freely positionable suspensions and large spans do not just make assembly possible, but at the same time allow an extremely flexible working range of both crane and load.

The corrosion-free profiles are long-lived and the maintenance work and associated costs are reduced to a minimum. The systems are highly competitive, and not just in terms of the cost of acquisition.

LIGHTster benefits

-

Low own-weight

Can also be used in application areas capable of bearing only low static loads; ergonomic, time-saving assembly; low number of freely positionable securing points -

High quality

Non-corrosive material, diminished operating noises thanks to state-of-the-art nylon wheels, prolonged service life with low maintenance costs -

Precise application

Low vibration load movement; exact flow of materials; simple, ergonomic handling even without motorisation

LIGHTster types

-

Single girder low headroom

- Recommended for low headroom conditions

- Significantly improves the vertical hook stroke of the hoist

- Recommended with a motorized bridge movement

-

Single girder rigid

- Recommended solution for bridge spans higher than 6m

- Recommended with a motorized bridge movement

- Triangular (rigid) bridge construction prevents any crab motion

-

Single girder articulated

- Recommended solution for maximum bridge spans of 6m

- Recommended solution for manually operated bridge motions

- Articulated bridge construction allows for crab motion of the bridge easily

-

Double girder low headroom

- Very short headroom and a maximum possible vertical hook stroke

- Recommended with a motorized bridge movement

-

Double girder rigid

- Recommended with a motorized bridge movement

- Triangular (rigid) bridge construction prevents any crab motion

-

Double girder articulated

- Recommended solution for maximum bridge spans of 6m

- Recommended solution for manually operated bridge motions

- Articulated bridge construction allows for crab motion of the bridge easily

Key technical data

-

Capacities up to 2,000 kg

-

Light weight

-

Intelligent connection system for easy installation

-

Wide range of profiles available

-

Inner runner protected from dirt and dust by the enclosed design

-

Low running noise

-

Suitable for large spans

-

Single- and double-girder solutions

-

Normal and low headroom